Filling machines have risen in popularity since they are efficient and can help bulk packaging of various products. The cutting edge technology enables high production capacity along with the flexibility to monitor the process. If you are curious about the different types of filling machines available and how they work technically, here a quick guide to help you understand the process briefly!

Working Principle of Tube Filling Machine

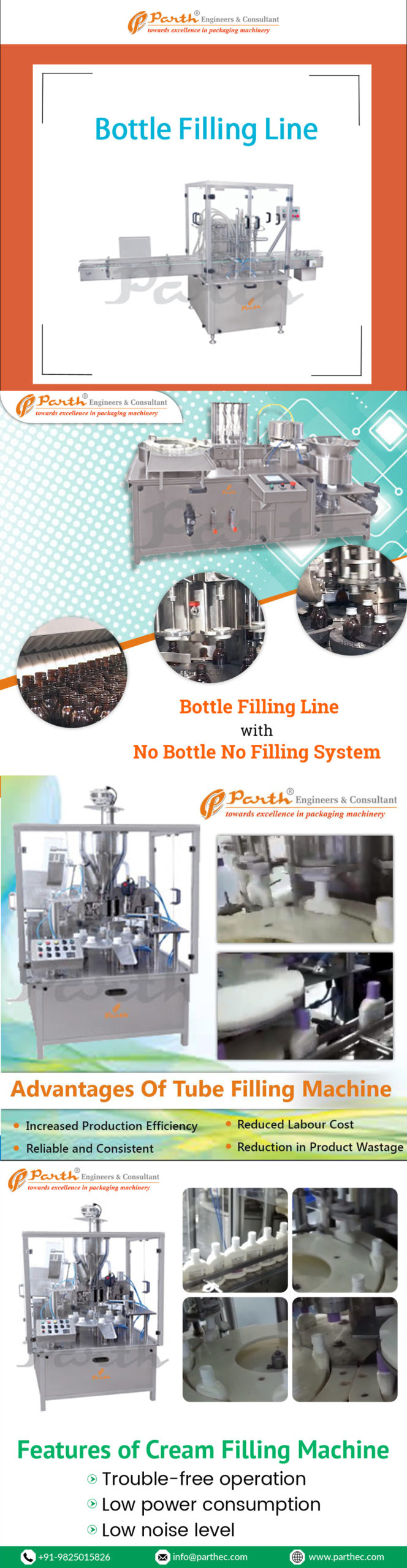

As the name suggests, a tube filling machine assists in the manufacturing of aluminum, plastic, and glass tubes. The equipment can help filling up creams, ointment, and similar viscous products into tubes with a sophisticated volumetric dosing system. It also a speed control technology to fill up your products in the shortest time possible.

Here’s how a Tube Filling Machine Works:

- The machine is available with an automatic and semi-automatic operating system. It means that you can conduct the packaging process in an organized sequence.

- The process starts with filling, sealing, printing the batch number, and many other functions. These functions take place at different intervals at specific workstations.

- The best thing about this advanced machine is that you can determine the rate of filling and choose the machine’s capacity as per your unique requirements. That way, you can achieve consistency and accuracy.

Working Principle of Cream Filling Machine

A cream filling machine is similar to a paste filling machine that helps in the packaging of liquids, semi-liquids, and other viscous materials. The cream filling machine can help you consistently fill various containers such as jars, tubes, and many others with a flexible and adjustable control mechanism. The equipment has found wide-spread usage across the pharmaceutical, food, and nutraceutical industry.

The working principle of a cream filling machine includes:

- The ointment filling machine uses a volumetric method to measure the contents with precision. You can adjust the plunger volume to make sure that the filling quantity is as per your requirements.

- If you choose an automatic system, it will be handy for viscous materials as it comes with dynamic settings for precision control. It does not even let contaminants enter into the container. This is particularly useful for industries where hygiene is a determining packaging factor.

Working Principle of Bottle Filling Machine

Whether you are new to the liquid filling world or looking to upgrade your existing production line, a bottle filling machine is an ideal addition. You can choose an automatic volumetric liquid filling machine as they are flexible with several surfaces, including aluminum, glass, plastic, and many others. They have a sizable conveyor that is ideal for larger-scale operations with high-speed requirements.

How the Working Principle of a Bottle Filling Machine Can Help You:

- Based on unique requirements, the automatic liquid filling line is available in gravity, vacuum, and pressure mechanisms. Vacuum systems can assist you with the packaging of high viscosity liquids and syrups. On the other hand, gravity fillers are ideal for free-flowing liquid.

- While choosing a syrup filling machine for your business, you should consider your product and the container type to make an informed decision.

Working Principle of Jar Filling Machine

Filler machines for containers such as jars and cans are ideal for the food and the pharmaceutical industry. They can help in filling and sealing liquids and viscous materials into the container.

The working of the jar filling line is similar to a normal filling machine. You can set up the system as per the required balance, timing, and calibration.