For Export Enquiry

Call Us

How to Optimize Dry Powder Filling Machines for Multi-Dose Vial Systems in High-Volume Pharma Production?

Listen to the Audio Version

Objective

In pharmaceutical manufacturing, high-volume production of injectable drugs, particularly in multi-dose vial systems, demands utmost precision, efficiency and reliability in the filling and sealing process. Dry powder filling machines are crucial in these operations, as they ensure that the correct amount of medication is dispensed in every vial, without compromising on product quality or production speed. This article aims to explore the various strategies for optimizing dry powder filling machines for multi-dose vial systems, particularly in high-volume pharmaceutical production settings.

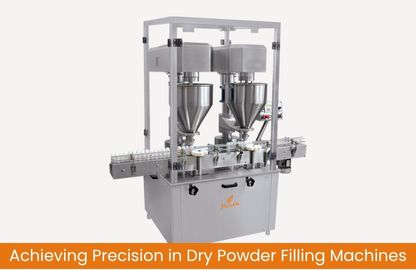

How Can Precision and Accuracy Be Achieved in Dry Powder Filling Machines?

One of the core requirements for optimizing dry powder filling machines is ensuring precise dosing. This is particularly important when filling multi-dose vials, where the drug formulation must be consistent across all doses.

Dry powder filling machines often incorporate technologies such as gravimetric, volumetric or net weight measurement systems. These ensure the correct quantity of dry powder is dispensed. Calibration and maintenance of these systems are critical to prevent errors. Machine performance can be optimized by setting up an effective calibration schedule and implementing automatic feedback systems to adjust the filling volume in real-time.

How Can Dry Powder Filling Machines Be Made More Flexible for Different Vial Sizes?

Multi-dose vial systems come in different sizes, which requires dry powder filling machines to be versatile. To accommodate varying vial capacities, the machines should feature adjustable filling heads and specialized molds or containers that can handle different vial designs without compromising the filling speed or accuracy.

Automating the changeover process for different vial sizes can improve the efficiency of the filling line and reduce downtime between production runs. This can be achieved by installing modular components that allow for rapid reconfiguration, ensuring minimal disruption during production.

What Are the Best Practices for Controlling Contamination During the Dry Powder Filling Process?

Ensuring that the dry powder remains free from contamination is a key challenge in pharmaceutical production. Even minute contamination can lead to product failures and safety concerns. To optimize dry powder filling machines for multi-dose vials, it is essential to incorporate stringent contamination control systems.

This includes the use of isolators, clean rooms and HEPA filters to maintain an ultra-clean environment. The machines can also be equipped with sterile filling systems that prevent the introduction of foreign particles during the filling process.

Moreover, dry powder filler can be optimized with integrated sealing systems that ensure vials are tightly sealed after filling. This helps maintain the sterility of the product and prevents contamination from external sources during storage or transport.

How Can Dry Powder Filling Machines Be Integrated into an Automated Filling and Sealing Line?

For high-volume pharmaceutical production, integrating the dry powder filling machine into a fully automated filling and sealing line is essential for streamlining the manufacturing process. This can include automated vial washing, filling and sealing, followed by inspection systems for detecting any vial defects or improper seals.

An optimized dry powder filling line with automated inspection and rejection systems can help reduce human error, increase throughput and ensure compliance with regulatory standards. This integration also allows for better traceability and record-keeping, which is increasingly important in the pharmaceutical industry.

What Role Does Maintenance Play in Optimizing Dry Powder Filling Machines?

Regular maintenance is essential for ensuring that dry powder filling machines perform optimally. Downtime due to machine malfunction can result in costly delays in production and potential loss of product. To mitigate these risks, it is advisable to implement predictive maintenance systems that monitor key components for wear and tear, as well as overall machine performance.

By employing real-time monitoring systems, machine operators can be alerted to potential issues before they cause a disruption in production. This proactive approach to maintenance helps reduce unplanned downtime and ensures that production schedules are adhered to, without sacrificing quality or output.

How Can Energy Efficiency and Waste Reduction Be Achieved in Dry Powder Filling?

In high-volume pharmaceutical production, optimizing energy consumption is another important consideration. Dry powder filling equipment can be optimized to operate with minimal energy consumption by incorporating energy-efficient motors, drives and heat exchangers. This may not only reduce production costs but also lower the environmental impact of the manufacturing process.

In addition, reducing waste during the filling process can significantly improve overall production efficiency. This includes minimizing powder spillage, optimizing powder recovery and ensuring that excess material is not discarded. Implementing powder recovery systems can help reclaim unused material, reducing the overall cost of production.

Conclusion

Optimizing dry powder filling machines for multi-dose vial systems in high-volume pharmaceutical production is a complex yet critical task. By focusing on key aspects such as precision in dosing, contamination control, machine flexibility and automation, pharmaceutical manufacturers can improve production efficiency, reduce waste and maintain product quality. The integration of advanced technologies can further enhance the performance of dry powder filling lines, providing manufacturers with the tools they need to meet the demands of modern pharmaceutical production. Continuous optimization and innovation in this area are essential for staying competitive and ensuring the safety and efficacy of pharmaceutical products.

FAQs About Dry Powder Filling Machine

Dry powder filling machines typically use volumetric, gravimetric or net weight measurement systems to ensure the accurate dispensing of powder. These systems are calibrated and maintained to ensure precision in filling.

Yes, dry powder filling machines can be optimized for different vial sizes through adjustable filling heads, specialized molds and modular components, allowing for flexibility and reduced downtime between production runs.

Contamination can be controlled using isolators, clean rooms, HEPA filters and sterile filling systems. Machines are also equipped with sealing systems to ensure the vials are tightly sealed, preventing contamination during storage or transport.

Modern dry powder filling machines integrate advanced technologies monitor production data, improve accuracy and optimize maintenance schedules for better performance.

Predictive maintenance systems monitor machine components for wear and tear, alerting operators to potential issues before they disrupt production. This helps minimize downtime and keeps the machine operating at peak efficiency.

About Author

We provide 24 x 7 Customer

Service & Support

Copyright © 2026, Parth Engineering & Consultant ( India ).

Web Design by Opal Infotech