For Export Enquiry

Call Us

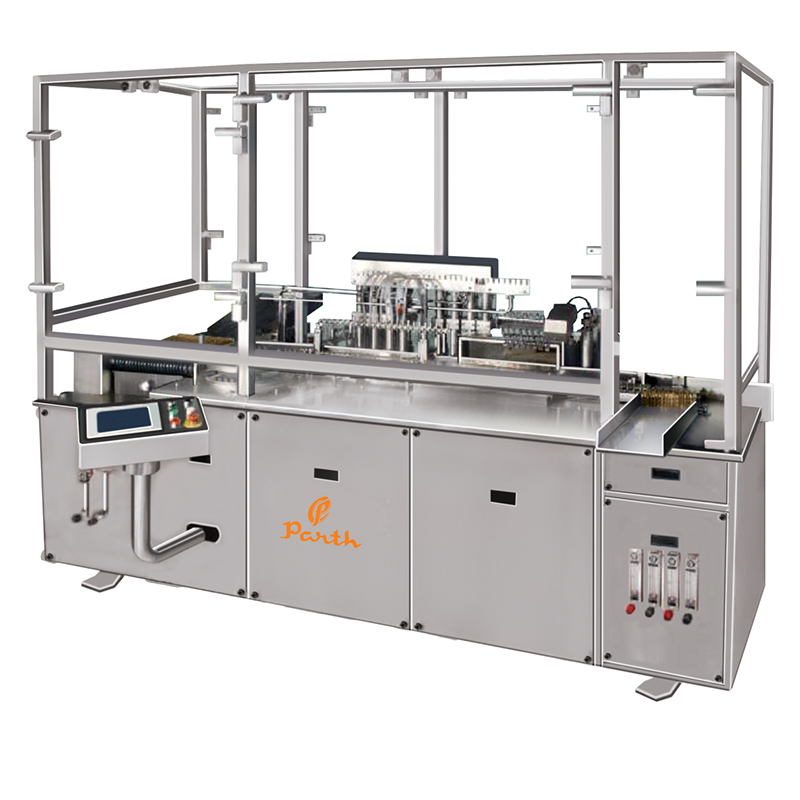

Ampoule Filling & Sealing Machine Line

Premium Ampoule Filling & Sealing Solutions

When it comes to top-of-the-line Ampoule Filling & Sealing solutions, Parth Engineers & Consultant take immense pride in offering the best quality machinery to meet the needs of pharmaceutical companies and ensure the integrity of their products. Our Ampoule Filling & Sealing Machine Line comprises a range of highly efficient and versatile equipment, including Automatic Rotary Ampoule Washing Machines, Automatic Ampoule Filling & Sealing Machines, and Automatic Ampoule Sticker Labeling Machines.

Key Features of Ampoule Filling & Sealing Machine:

- Cutting-Edge Technology: Our machinery is equipped with cutting-edge technology to ensure the highest level of performance and precision.

- Exceptional Quality: We are dedicated to delivering products of exceptional quality, guaranteeing reliable and consistent results.

- Versatility: Our product line caters to various requirements, from washing and filling to sealing and labeling ampoules.

Automatic Rotary Ampoule Washing Machines

At Parth Engineers & Consultant, we offer Automatic Rotary Ampoule Washing Machines that are designed to meet the most demanding cleaning standards. These rotary ampoule washing machines can effectively clean a wide range of ampoule sizes, ensuring that they are free from contaminants and ready for the filling and sealing process.

Automatic Ampoule Filling & Sealing Machines

Our Automatic Ampoule Filling & Sealing Machines are the epitome of efficiency and accuracy. These ampoule filling and sealing machines are engineered to streamline the filling and sealing process, ensuring that each ampoule is filled precisely and sealed hermetically to maintain the product's quality and safety.

Automatic Ampoule Sticker Labeling Machines

For pharmaceutical companies looking for a complete solution that includes labeling, our Automatic Ampoule Sticker Labeling Machines are the perfect choice. These ampoule sticker labeling machines apply labels to ampoules with precision, providing a professional and attractive finish to your products.

Parth Engineers & Consultant offers a comprehensive line of Ampoule Filling & Sealing Machinery that meets the highest industry standards. Our dedication to quality, precision, and versatility makes us the go-to choice for pharmaceutical companies seeking to enhance their production processes. With our state-of-the-art technology and commitment to excellence, we ensure that your pharmaceutical products are in safe hands throughout the manufacturing process, from washing and filling to sealing and labeling.

FAQs for Ampoule Filling & Sealing Machine Line

Parth Engineers & Consultant provides a diverse range of Ampoule Filling & Sealing Machines tailored to meet the needs of the pharmaceutical industry. This lineup includes Automatic Rotary Ampoule Washing Machines, which are designed to meet stringent cleaning standards and are capable of handling various ampoule sizes. We also offer Automatic Ampoule Filling & Sealing Machines that streamline the filling and sealing process with high precision and efficiency. Additionally, our Automatic Ampoule Sticker Labeling Machines are perfect for companies looking for a complete solution that includes precise and professional labeling capabilities.

The Automatic Rotary Ampoule Washing Machine from Parth Engineers & Consultant ensures product safety by thoroughly cleaning ampoules before the filling process. It effectively removes all particulate matter and potential contaminants, ensuring that ampoules are free from impurities. This process is crucial as it prepares ampoules for a contaminant-free filling and sealing process, thereby preserving the integrity and efficacy of the pharmaceutical products.

The Automatic Ampoule Filling & Sealing Machines from Parth Engineers & Consultant offer significant advantages that enhance both the efficiency and reliability of pharmaceutical manufacturing. These machines ensure precise dosage with each ampoule, maintain hermetic sealing to protect the contents from air and contaminants, and significantly increase production efficiency. By automating the filling and sealing process, these machines also help reduce labor costs and enhance overall throughput, crucial for high-volume pharmaceutical production.

Our Automatic Ampoule Sticker Labeling Machines are engineered to enhance labeling accuracy and consistency. These machines apply labels precisely, ensuring perfect alignment and placement on each ampoule. They are designed to handle high volumes quickly, thus maintaining pace with the rest of the production processes. Accurate labeling is essential not only for delivering critical product information but also for improving the visual appeal of the products, which is important in competitive pharmaceutical markets.

Choosing Parth Engineers & Consultant for your ampoule filling and sealing solutions provides several benefits. We utilize the latest technology to ensure our machines are both reliable and perform at the highest standards. Our commitment to quality means that we provide machinery that consistently meets the rigorous demands of pharmaceutical production. Additionally, our solutions are versatile and can be customized to meet specific production needs, making us a preferred partner for pharmaceutical companies looking to optimize their production processes and enhance product quality.

We provide 24 x 7 Customer

Service & Support

Copyright © 2025, Parth Engineering & Consultant ( India ).

Web Design by Opal Infotech