For Export Enquiry

Call Us

Different Types Of Dry Syrup Powder Filling Machines

Why Medicine Sector Prefer Dry Syrup?

There are certain logical benefits in preparing medication in powder form and they are,

- Preparation of drugs in granule form can help to avoid stability issues.

- Prevents changes in viscosity, which is found to be one of the critical problems in liquid syrup preparation.

- Powder form of syrup helps to avoid crystal formation.

- Does not get affected by climatic changes as the medication is purely in granule form without space for moisture or water content.

- Easy for shipping and cost effective as these are comparatively light weight.

How Filling Machines are Beneficial to this process?

Dry syrup powder filling machine are designed in different forms to meet the growing requirements of industries. These are automatic equipments and reduce the risk of spillage, unnecessary exposure of medication to atmosphere and save much time in packaging. Apart from that, processes starting from measuring to filling in respective containers take place immediately and in short time. When compared to manual stuffing, these equipments cannot be excelled in speed, accuracy, and deliverance of stuffed containers.

Qualitative Range of Powder Filling Machines for Drug Industry

Drug industry is the most challenging and critical of all when it comes to packing. Dry syrup filling machine has a special role to play as precision of quantity remains mandatory to maintain the imposed limits of dosage. Automatic machines for filling powder provide significant advantages to pharmaceutical industry. Apart from that, considering the critical issues related to drug stability, dosage and regulatory factors there have been special range of equipments designed for filling. These are exclusive in design and help to obtain dosing flexibility. These filling devices are of different types and they are designed as per the industrial standards and production requirements.

Automatic 16×8 Head Rotary Dry Syrup Powder Filling Device is equipped with automatic functionality and designed with 16 head powder filling capacity. It suits best for handling PET, HDPE and LDPE bottles and fill 4000-6000 Containers. In addition to that, this machine works on vacuum and air systems for stuffing and exhibits high speed performance with the help of rotary bottle moving system. Wastage prevention is another advantage in using this equipment.

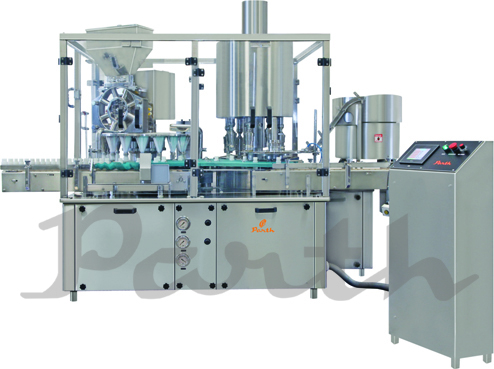

Automatic High Speed Rotary Dry Syrup 16X8 Powder Filling and Capping Machine

This machine has all the features like that of 16 head rotary powder filling devices however; it has been featured with capping operation. The out feed star wheel and capping has been synchronized to provide smooth stuffing and sealing at very high speed. It can be applied with ROPP and for capping it stays compatible to handle any kind of cap.

Double and Single Head Augur Type Machine

Automatic single head or double head augur type dry syrup filling equipment are compatible forms of packaging devices that stays flexible for handling different shapes of containers, bottles, etc. It can stuff up to 600-1200 Container per hours and the speed varies depending on the volume of product and the shape of the container. However, this equipment is one of the economic ranges of filling machines for pharmaceutical industry.

Conclusion

Powder stuffing equipments for medicine sector favors more benefits in terms of performance and accuracy. Parthec is one of the leading manufacturers and suppliers of pharmaceutical packaging equipments that designs varieties of machines for stuffing medicines in granule form. These are cost-effective and stay good in quality.

We provide 24 x 7 Customer

Service & Support

Copyright © 2025, Parth Engineering & Consultant ( India ).

Web Design by Opal Infotech