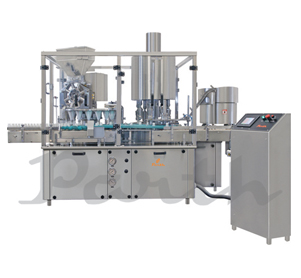

A Glass Jar Capping Machine is a piece of capping equipment that drops caps down a track. This piece of equipment is used to cap glass-bottled liquids. Its automated mechanism has a chuck attached to the motor that picks up the cap and arranges it on the bottle. This machine can be customized to suit the type of container and the type of cap required. It is made of stainless steel and is suitable for capping glass jars.

Important Features of Automatic Jar Capping Machine

The Automatic Capping Machine applies the caps on glass bottles and pails. The machine is very efficient and is easily adjustable to accommodate different-sized caps. The machine has an adjustable height of conveyor line with a torque adjustment with a compressed air inlet. This machine can also close metal cans and plastic pails.

Working of Automatic Capping Machine

The automatic filling and capping machine combines electricity and pneumatics to ensure that caps stay securely on the bottles. The jars and containers can be filled by hand or automatically. The jars are placed into a conveyor and capped bottles are sent out. The rotary screwing mechanism secures the caps on the containers. Once the jars are complete, the capper sends them out on a conveyor.

A Jar Capping Machine should be able to perform the job of applying threaded caps to bottles. The capping station is made up of a column with a releasing head and press-on closing heads. A distributor should be able to easily handle the capping task and distribute the caps to the containers. It also needs to be capable of performing various tasks that are necessary for the production of the products in a company.

Benefits of Using Automatic Jar Capping Machine

There are several benefits to using a jar capping machine. It helps save time and money on the product line. It also guarantees a clean working environment. It is simple to use its high-speed closures. Your life will be easier with a jar capping machine. For every packaging firm, a jar capping machine is a useful tool. It’s a wise decision to make. This piece of machinery is available in various models. A single model may be suitable for small businesses.

The Bottom Line

Several types of jar capping machines are available on the market. They can handle different types of containers and provide multiple sizes. A single machine can handle several kinds of jars. A vertical jar capping machine can be configured to meet different container heights and is suitable for small-scale companies. A horizontal jar capping machine can also be used for large-scale production and is also suitable for medium to small-scale packaging.