Types of Bottle Labeling Machines

A bottle labeling machine is a great investment for any home business owner or entrepreneur. This is because it can help you make more money by printing labels with ease. Plus, it can help save you time on your job. It can also help keep your company’s products organized and clean.

Labeling Machine for Round Vs Square Bottles

If you are in the market for a bottle labeling machine, you may be wondering which type to purchase – a round or square bottle applicator. While the two are equally functional, there are certain differences.

A round bottle is easier to handle, while a square bottle is harder. Square bottles also require more care when applying labels. That said, a square bottle labeling machine can be used for a number of applications, from food packaging to pharmaceutical products.

The most important factor when choosing a bottle labeling machine is the amount of bottles it can handle. Depending on your needs, you can choose from a small machine or one that can handle 600 bottles per hour.

For smaller batches, you can opt for a manual square bottle applicator. It will allow you to apply labels with ease, while ensuring accuracy and convenience.

Bottle Labeling Machine for Paper Label Vs Foil Vs Film

If you’re looking for a good way to label bottles, you’ve probably considered using film or paper labels. In fact, these two types of materials have their own benefits and drawbacks. For starters, the durability of a label can vary drastically.

Paper isn’t quite as durable as film. It’s more likely to wrinkle, and its wet strength is often diminished.

Fortunately, there are some alternatives that can make up for the shortfalls. One example is repositionable labels. These adhesives are softer and can move with the bottle. However, this requires a more complicated machine.

Another option is foil. This type of label isn’t as expensive as a film product, and isn’t as vulnerable to damage. Plus, it has a number of other unique qualities. The main one is the fact that it can be used for a wide range of applications.

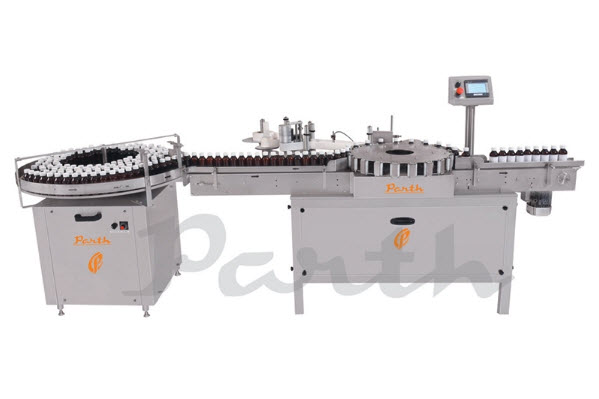

Bottle Labeling Machine

Parth Engineers & Consultant bottle labeling machines are an important part of the liquid packaging process. These machines apply customized labels and logos. We also provide a high degree of accuracy and flexibility. The right machine will allow you to make the best use of your production line.

Labeling machines are broken down into four basic configurations. Depending on your needs, you may need a machine with multiple stations or one that is flexible enough to handle production speed changes.

There can be an option to add a hot stamp or laser printer to the labeling machine. Hot stamps allow for precise printing. Laser coders can code individual serial numbers and can print text at extremely high speeds.

The labeling machine can accommodate bottles of different sizes and shapes. It is necessary to position each bottle in a way that will minimize the risk of air getting under the label. This will affect the adhesion and sticking properties of the label.

Bottle labeling machines are designed to ensure accurate label placement. There are different models available, so you can choose the one that suits your needs.

Some models are designed to apply labels on two sides and the front of the bottle, while others can label the entire bottle. These are ideal for companies that need to apply labels on a lot of bottles. Moreover, they can be configured to suit any production capacity.

All bottle labeling machines use a conveyor system to move the bottles. The system is made from durable stainless steel and is fitted on top of the machine. It holds the labels, and moves them quickly and evenly throughout the labeling process.

Another important part of a bottle labeling machine is the control panel. It is used to set and control the parameters for the whole procedure. This allows users to select the settings and operate the machine from a single location.

A warranty for a bottle labeling machine is a no brainer. It’s a good way to save time and effort while getting a quality end product. For most businesses, it’s a win-win.

However, it’s not just about protecting your investment. You’ll also want to find out what type of warranty you get.