The filling line equipment is available in different capacities and caters to different specifications. These fillers can be manual, semi-automatic, and automatic and have reliable rates of output per minute. Their features are designed to add efficiency, consistency, and accuracy to the packaging process. The sturdy nature avoids any vibration and helps fill in the process without any spills. They are compatible with a vast majority of products and an overview of a few products is described below.

Injectable Powder Filling Line

The injectable powder filling machine is ideal equipment for adding injectable powder into vials. The clean containers are placed in the filling stations after thorough cleansing. After getting filled with suitable contents they are then transferred to the filling station. In the station of the powder filling station, the filled bottles get covered with a cap to prevent them from contamination. This automatic high-speed injectable dry powder filler with a rubber stoppering machine is a completely mechanically driven one and the filling is done with the help of a vacuum and air pressure-based powder wheel with a manual fill weight setting.

Dry Powder Filling Line

This filling line has the unmatchable speed to manage the speed of incoming and outcoming vials and has a built-in turntable at the infeed and the outfeed. They have a port powder wheel that works on vacuum and air systems to fill powder in glass vials. The dry powder filling line has an online vibrator-type rubber stoppering system that works in a continuous mode with the synchronized speed of the machine. The automatic powder level maintaining system is inherent for maintaining a constant level of powder to facilitate minimum weight variation. There are table models which are compact and easily movable.

Injectable Liquid Filling Line

This line has a variety of intermittent and continuous motion servo-based liquid vial systems with a full and half rubber stoppering machine. They are used to fill the sterile aqueous and viscous liquid in glass vials in an open restricted access barrier system. They are useful in the line of ampoule filling, liquid vials, and sterile powder, especially in the pharmaceutical industry. The minimal distance between the filling and stoppering units reduces the risk of contamination in the injectable liquid filling machine. The unscrambler has also been designed to eliminate dead ends and difficult-to-end spots.

Vial Filling and Bunging Line

The Vial filling and Bunging lines are designed to fill the liquid injection vials. The filler is a monobloc machine that can do filling and stoppering or bunging operations on the same platform. It is characterized by the presence of a peristaltic pump aseptic filling and has an easy validating system for small and large batch productions. Individual pumps can be adjusted and calibrated for the desired volume with the help of an easy use PLC. Any Oil-based material is easy to be filled with this machine because the specially designed peristaltic pump has the facility of suck-back.

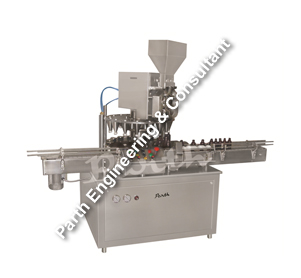

Dry Syrup Filling and Capping Machine

The Dry Syrup filling equipment helps to fill any solid particle or loose particle with varying degrees of fineness. They are available in a wide variety and have a monitoring system that allows accuracy in packaging. It also allows to fill large volume powder into PET/glass bottles and can fill maximum containers per minute depending on the type of powder, bottle diameter, and bottleneck diameter. The dry syrup filling and capping line has the benefits of a good sealing. It covers and seals the bottles immediately after sealing it to capacity.