For Export Enquiry

Call Us

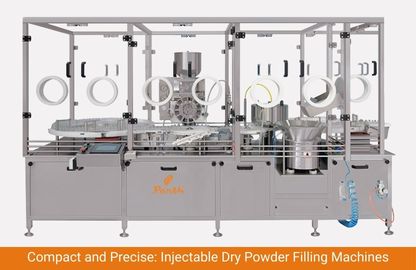

Designing Compact Injectable Dry Powder Filling Machine for Space-Constrained Pharma Plants

Listen to the Audio Version

Injectable Dry Powder Filling Machine for Space-Constrained Pharma Plants

This article explores the design, functionality and advantages of compact injectable dry powder filling machines tailored specifically for pharmaceutical manufacturing environments with limited space. The goal is to guide pharma professionals through the challenges of machine integration, performance and adaptability in space-constrained settings.

Understanding the Role of Injectable Powder Filling Machine in Pharma Production

Injectable powder filling machines play a crucial role in the sterile drug manufacturing process. These machines are responsible for accurately filling powdered formulations into vials in a clean, contamination-free environment. In today’s evolving pharmaceutical landscape, where real estate and operational costs are at a premium, the demand for compact, high-efficiency machines has grown significantly. Pharma companies are under constant pressure to maximize production in minimal space without compromising on safety or GMP compliance. This shift has brought machine design into sharper focus, pushing engineers to innovate more compact and efficient solutions.

The compact injectable powder filling machine not only optimizes space but also ensures accurate dosing, minimal product wastage and easy integration with vial washing, sterilization and capping units. This creates a seamless injectable liquid filling line, even in small production units. It’s this synergy between precision and design that supports modern pharmaceutical plants to remain agile and scalable.

Injectable Powder Filling Stoppering Machine: Enhancing Efficiency in Smaller Footprints

An injectable powder filling stoppering machine combines two critical functions - filling and partial or full stoppering - within a single, streamlined unit. The integration of servo mechanisms and vacuum-based pick-and-place systems has allowed manufacturers to reduce machine dimensions while maintaining high throughput.

In compact designs, every mechanical component must serve a dual purpose to conserve space. For example, servo-driven indexing wheels not only improve accuracy but also eliminate bulky mechanical linkages. The rubber stoppering system mounted on top ensures vertical utilization of space, making the most of a plant’s limited square footage. This thoughtful design enables uninterrupted operations even in compact cleanrooms where space must be reserved for operators and material movement.

Advanced features like touch-screen interfaces, recipe storage and auto-cleaning make these machines easy to manage even in tight quarters. With reduced machine size and enhanced functionality, pharma manufacturers no longer need to sacrifice efficiency for spatial constraints.

Read Our Article

Injectable Dry Powder Filling MachineInjectable Dry Powder Filling Machine: Compact Design, Complete Control

When it comes to filling dry powders into sterile vials, precision is everything. The injectable dry powder filling machine ensures consistent and accurate powder dispensing while maintaining sterility. Compact machines built for such environments are typically modular in nature, enabling them to fit into existing production lines without needing significant infrastructural changes.

Modular design means easier validation, better maintenance access and faster changeovers. These machines can be equipped with integrated vacuum powder feeding systems, multi-dose options and real-time feedback systems. All these features come together to create a high-performing unit that meets regulatory requirements without occupying much floor space.

Moreover, when integrated within an injectable liquid filling line, these machines complement liquid fillers by offering versatility in processing both powder and liquid dosage forms using minimal equipment real estate. This dual-use approach maximizes the value of every square foot in the plant.

Injectable Liquid Filling Line Integration with Compact Powder Filling Units

Pharmaceutical manufacturing demands flexibility. Combining a compact injectable dry powder filler within a broader injectable liquid filling line offers a unified solution for processing various injectable formats. This approach allows manufacturers to handle multiple products on the same line with quick changeovers, ideal for CDMOs and manufacturers managing small-batch production.

The dry powder and liquid fillers must be synchronized to maintain throughput and prevent bottlenecks. Today’s advanced software solutions make it possible to coordinate these units using centralized PLC and HMI systems. This creates a smart, unified operation that delivers efficiency even in a limited footprint.

Our Other Product

Automatic Rotary Ampoule Washing MachinesInjectable Liquid Filling Machine: Streamlining Processes in Compact Units

The injectable liquid filling machine is another essential part of the filling line, responsible for aseptically filling vials with liquid formulations. Compact models are designed with horizontal filling heads, servo-driven pistons and simplified change parts that significantly reduce the machine’s size.

Innovations in this area have also focused on ease of maintenance, tool-free adjustments and compatibility with isolator and RABS systems. With fewer moving parts and a smaller base frame, the machines occupy less floor area while providing reliable and consistent fill volumes.

They are often used alongside an injectable powder filler, especially when dealing with products requiring dual-form delivery or mixed-batch processing. The ability to integrate such machines in tight spaces makes them ideal for urban pharma facilities or companies operating out of smaller GMP-certified spaces.

Injectable Vial Filling Machine Design Considerations for Space Optimization

Designing an injectable vial filling machine for a space-constrained environment requires careful planning of each module. The configuration must allow easy access to all functional parts, streamline cleaning and validation and ensure no compromise on sterility.

Some key considerations include:

- Modular conveyors for smooth vial transfer

- Vertical and horizontal integration of components

- Minimal tubing to avoid clutter

- Efficient vial rejection systems

- Inline sensors for real-time monitoring

By focusing on vertical design, combining operations and simplifying mechanical architecture, the modern injectable vial filling machine can operate with high efficiency even in confined spaces. These designs help maintain compliance with pharma standards while making the best use of the available area.

Injectable Filling Machine Technology and Its Evolution for Smaller Plants

Technology has drastically influenced the development of compact injectable filling machines. From servo motors and smart sensors to AI-based analytics and remote operation capabilities, today's machines are far removed from the bulky, mechanical systems of the past.

By integrating automated dosing systems, compact cleanroom-compatible designs and ergonomic interfaces, manufacturers can achieve precision and control without expanding the plant layout. These innovations not only reduce footprint but also enhance productivity and operator safety.

In smaller plants, where scalability is key, this new generation of machines provides the flexibility to adapt production according to changing demands without additional space investment.

Injectable Liquid Filler Machine: Tailored for Small-Batch Production

Smaller pharmaceutical units often work with niche or specialty drugs, where batch sizes are limited but quality and compliance standards remain high. The injectable liquid filler machine has evolved to meet these needs by offering compact, flexible and multi-format designs.

With adjustable fill volumes, minimal changeover times and integrated CIP/SIP systems, these machines ensure sterility and accuracy. Their space-efficient build makes them the preferred choice for cleanroom environments where maximizing utility per square meter is critical.

Combining these units with dry powder systems further enhances the line’s versatility, enabling manufacturers to handle both drug forms with one integrated setup.

Injectable Powder Filler Integration in Turnkey Projects

The injectable powder filler is a vital component in turnkey projects for sterile drug production. For pharma plants with limited space, turnkey solutions built around compact machines ensure faster deployment and reduced capital investment in infrastructure.

These systems are often skid-mounted or modular, allowing them to be transported, installed and validated quickly. Their plug-and-play nature reduces downtime and simplifies regulatory audits. With design emphasis on size, safety and speed, injectable powder fillers can seamlessly fit into even the most constrained facilities.

Injectable Liquid Filler for Adaptive Pharma Environments

Modern pharma production demands quick adaptability. The injectable liquid filler, when designed with compact, smart features, becomes an ideal solution for facilities that must adapt to changing formulations and production demands.

Their modular construction and intuitive control systems make them easy to reconfigure for different vial sizes or fill volumes. This capability is especially valuable in adaptive facilities or pilot-scale environments where every inch of space counts.

Injectable Dry Powder Filler: Space-Efficient Dosing without Compromise

The injectable dry powder filler delivers exceptional dosing accuracy in a highly condensed machine footprint. These machines are engineered with vacuum-assisted dosing systems, minimal residual powder loss and anti-static features - all packed into a slim design.

They are best suited for lyophilized drugs, antibiotics and specialized formulations requiring powder dosing under sterile conditions. Their compactness allows for flexible placement within cleanroom suites, supporting lean manufacturing models.

Our Other Product

Automatic Ampoule Filling & Sealing MachineCompany Profile Highlight: Parth Engineers & Consultant

One of the standout contributors to compact pharma packaging machinery is Parth Engineers & Consultant, a trusted name in the industry since 1995. Based in Ahmedabad, India, the company specializes in manufacturing high-performance machinery such as injectable liquid vial filling machine, rotary washing machines and bottle labeling machines.

With decades of experience and an innovative mindset, Parth Engineers has emerged as a leader in compact, efficient and GMP-compliant equipment. Their expertise spans across industries, offering solutions tailored to pharmaceutical, dairy, distillery and chemical sectors. By focusing on modular, easy-to-operate and space-saving designs, the company continues to support pharma firms globally in optimizing production within spatial limitations.

Their dedication to engineering excellence and client satisfaction is evident in the high-quality machines they deliver - ideal for modern pharmaceutical plants dealing with space and compliance challenges.

Injectable Liquid Filling Line Customization for Space-Conscious Plants

Not all facilities are built the same. Customizing an injectable liquid filling line for a space-conscious plant involves more than just shrinking machine size. It’s about designing a complete ecosystem that maintains production flow without bottlenecks.

From integrating powder fillers and vial washers to ensuring ergonomic access for operators, customization allows for better space utilization, improved productivity and compliance with GMP and international regulatory standards. Such tailor-made solutions are what help compact facilities match the output of larger plants.

Final Thoughts

Designing compact injectable dry powder filling machines for space-constrained pharma plants is no longer just an option - it’s a necessity. As pharmaceutical companies push for better efficiency, faster turnaround times and higher standards of sterility, machinery must evolve accordingly. The ability to maintain high performance in a smaller footprint is reshaping the future of sterile injectable production.

From powder fillers and liquid fillers to fully integrated lines, manufacturers now have access to smart, scalable and compliant solutions. Companies like Parth Engineers & Consultant are leading the way with innovative machines that meet the unique demands of modern pharmaceutical environments.

FAQs About Injectable Dry Powder Filling Machine

It saves space while maintaining precision and sterile conditions in pharmaceutical filling processes.

By integrating both filling and stoppering in a single compact system, reducing footprint and process time.

Yes, modular systems allow integration of both powder and liquid fillers in one efficient line.

They allow more efficient production within limited cleanroom space, reducing overhead and infrastructure costs.

Their innovative, compact designs and decades of experience make them a reliable partner for pharma packaging needs.

About Author

We provide 24 x 7 Customer

Service & Support

Copyright © 2026, Parth Engineering & Consultant ( India ).

Web Design by Opal Infotech