For Export Enquiry

Call Us

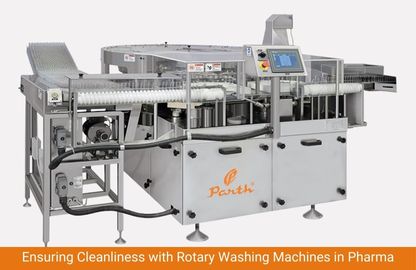

Rotary Washing Machine Stations: Building a Reliable Sequence for Internal & External Cleaning

Listen to the Audio Version

Rotary Washing Machine Stations: Sequence for Internal & External Cleaning

This article explores the operational principles, process sequences and the technological innovations involved in rotary washing machine stations, especially for cleaning internal and external surfaces of ampoules, vials and bottles. It also highlights the role of manufacturers like Parth Engineers & Consultant in advancing pharma packaging technology.

Understanding the Role of Rotary Washing Machine Stations

In the pharmaceutical industry, cleanliness isn’t just a quality - it’s a requirement. Every container, whether it’s a vial, ampoule or bottle, must be free from particles, contaminants and microbial residue before filling. This is where rotary washing machine stations play a crucial role. These systems are engineered to deliver consistent and precise cleaning, ensuring each container is thoroughly washed both internally and externally. The use of rotary mechanisms allows for a continuous, uniform cleaning process, optimizing efficiency without compromising on quality. This technology eliminates manual intervention, reduces contamination risk and enhances compliance with stringent industry standards.

Rotary Bottle Washing Machine: A Reliable Solution for Consistent Cleanliness

The rotary bottle washing machine stands out as an indispensable asset in large-scale pharmaceutical bottling. It handles a high volume of containers while maintaining integrity and hygiene. Bottles are automatically loaded, securely gripped, inverted and exposed to various cleaning jets. Internal rinsing with purified water ensures no residue remains, while the external surface is sprayed to remove dust or external contaminants. These washing stations are customizable and can handle different bottle sizes and shapes, making them ideal for operations that demand flexibility and productivity.

Read Our Article

The Benefits Of A Bottle Washing MachineRotary Vial Washing Machine and Its Precision Approach

A rotary vial washing machine offers unmatched precision when it comes to washing small and fragile containers like vials. These machines are carefully designed with synchronized spray needles that insert into the vials at specific intervals, jetting cleaning media in a controlled fashion. The rotation ensures that each vial is treated uniformly, while also maintaining the orientation necessary for proper drainage. Vials are then air-dried or moved directly to the sterilization stage. This machine ensures minimal breakage, reduced human error and complete sanitation - key factors in injectable drug production.

Rotary Ampoule Washing Machines for Internal & External Cleaning

Ampoules are among the most sensitive pharmaceutical containers due to their slender necks and sealed tops. A rotary ampoule washing machine ensures comprehensive cleaning while maintaining the structural integrity of these fragile glass vessels. During the washing process, ampoules are rotated, inverted and subjected to high-pressure sprays through specially designed needles that enter each ampoule at the right moment. The rotary mechanism ensures continuous movement, which helps streamline the washing, draining and transfer sequence. This minimizes downtime, supports scalability and aligns with high-output production lines.

Optimizing Efficiency with Rotary Capping Machine Integration

Following the washing and filling process, a rotary capping machine plays a critical role in securing pharmaceutical containers. The rotary system provides continuous capping without the need for stop-start mechanisms, which could affect speed and alignment. These machines offer torque control, cap placement precision and sealing consistency. When combined with rotary washing systems, they create a seamless and integrated packaging line. This synchronization improves line efficiency, reduces handling and contributes to a sterile workflow that supports pharmaceutical quality assurance.

Our Other Product

Augur Type Powder Filling MachineBuilding Seamless Production Lines with Rotary Filling and Capping Machine

The inclusion of a rotary filling and capping machine creates a synchronized bridge between the washed containers and their final sealing. These machines are capable of filling a wide range of liquid viscosities into washed vials or ampoules with high accuracy. The rotary format allows containers to be filled while continuously moving through the system. Once filled, they are capped or sealed within the same motion cycle. The efficiency gained here translates directly into time savings and enhanced throughput for pharmaceutical manufacturers aiming to scale production without sacrificing quality.

Rotary Vial Washer: Enhancing Sterile Manufacturing Environments

A rotary vial washer is purpose-built to serve sterile filling lines, where contamination control is paramount. Its automated cleaning stages typically include pre-wash, main wash and final rinse, often using a combination of sterile air, WFI and detergents. The design of these machines ensures zero retention of cleaning fluids and complete draining from each vial. This feature not only conserves water but also guarantees that each vial exits the washer in a sterilizable state. In a regulated industry, such levels of hygiene are essential to meet cGMP guidelines and regulatory expectations.

Rotary Ampoule Washing Machine: Engineering the Flow for Consistency

The operational flow of a rotary ampoule washing machine is a testament to modern engineering. Ampoules are fed through a hopper, singled out with precision screws and placed onto star wheels. The gripper arms then invert each ampoule, which is essential for targeted internal cleaning. Needles precisely align with the ampoule openings and the cleaning fluids are jetted inside while the containers move in sync. The entire process, from infeed to outfeed, is designed for high speed and absolute consistency. These systems can be adjusted for different ampoule sizes, offering versatility in sterile manufacturing.

Rotary Labeling Machine and Its Contribution to Post-Cleaning Processes

Once a container is washed, filled and sealed, it must be identified correctly before packaging. A rotary labeling machine ensures that this step is completed with precision and speed. These machines accommodate different container sizes and label formats. The rotary action holds the containers steady while the labels are applied with high accuracy. This avoids label misplacement and ensures compliance with pharmaceutical labeling requirements. Integrating this machine at the end of the production line helps maintain product traceability and facilitates smooth downstream packaging operations.

Innovations from Parth Engineers & Consultant

Among the notable contributors in the pharmaceutical machinery space, Parth Engineers & Consultant stands out for their advanced engineering and manufacturing capabilities. Since its inception, the company has become a trusted name in the development of high-quality equipment such as the Bottle Labeling Machine, Injectable Dry Powder Filling Machine and Injectable Liquid Vial Filling Machine.

Located in Ahmedabad, the company is known for delivering packaging solutions that meet both domestic and international standards. With decades of experience, Parth Engineers & Consultant has pioneered machinery innovations that cater to pharmaceuticals, dairy, beverages and chemical sectors. Their packaging lines are crafted with an emphasis on precision, durability and efficiency, making them a preferred choice for pharmaceutical manufacturers across the globe.

Streamlining Internal & External Washing Sequences for Better Output

When building a reliable washing station, the sequence of operations matters. The journey starts at the infeed, where containers are separated and aligned. This step is crucial to avoid breakage and jams. Once positioned, containers are inverted, typically using rotary mechanisms, exposing internal surfaces for targeted cleaning. Spray needles deliver cleaning agents in a synchronized manner, ensuring maximum coverage. External cleaning nozzles follow, blasting away any surface particulates. Post-wash, containers are re-inverted and passed down the line for drying, filling and sealing.

Every stage must align perfectly. Any delay, misalignment or variation in pressure could result in inconsistent cleaning. That’s why the rotary design, with its constant motion and synchronized tooling, offers a higher degree of reliability than linear systems. The washing station becomes not just a utility, but a foundation for sterile production.

Read Our Article

Pharmaceutical Vial Labeling And Washing MachineRotary Washing Machine Stations: The Backbone of Sterile Processing

In essence, rotary washing machine stations aren’t just equipment - they are the core infrastructure that supports high-volume, sterile pharmaceutical packaging. Their rotary movement eliminates stop-start bottlenecks, allowing processes to flow smoothly. Whether it's a vial, ampoule or bottle, the washing mechanism treats every container with uniform care. The automated precision offered by rotary systems supports traceability, batch consistency and regulatory compliance.

Companies that invest in advanced rotary washing stations experience fewer downtimes, improved product quality and greater customer confidence. And with manufacturers like Parth Engineers & Consultant offering turnkey solutions, it’s easier than ever to implement these high-performance machines into your production line.

FAQs About Rotary Washing Machine

It is used to clean both internal and external surfaces of containers like ampoules, vials and bottles before filling.

It uses synchronized spray needles that insert into inverted ampoules, delivering cleaning media precisely.

Rotary systems offer continuous motion, higher speed, uniform cleaning and better integration with downstream equipment.

Their experience, innovation and international-quality machinery make them a trusted name in pharmaceutical packaging solutions.

Yes, they are designed for flexibility and can accommodate ampoules, vials and bottles of various sizes.

About Author

We provide 24 x 7 Customer

Service & Support

Copyright © 2026, Parth Engineering & Consultant ( India ).

Web Design by Opal Infotech