For Export Enquiry

Call Us

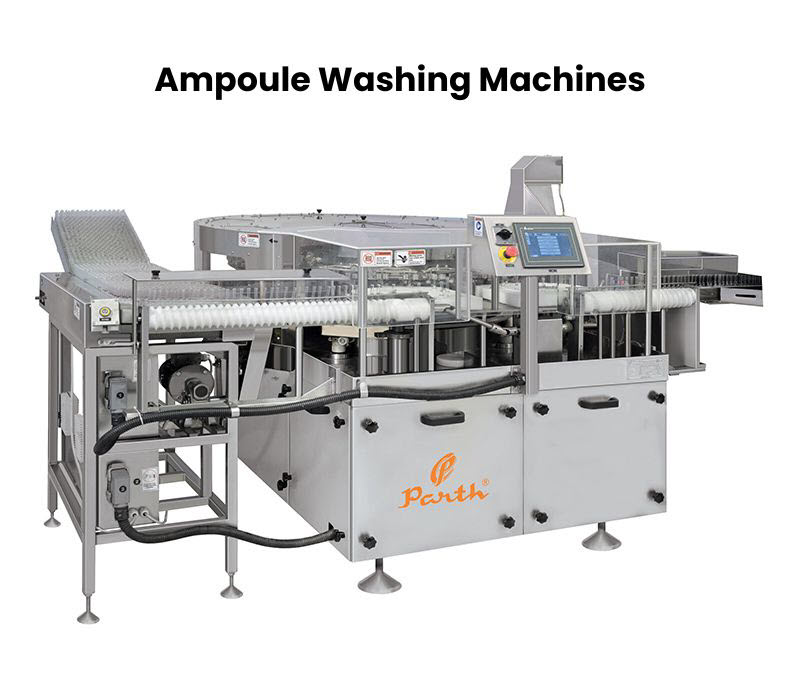

The Benefits of Easy Changeover in Automatic Ampoule Washing Machines: Reducing Downtime & Improving Maintenance

Listen to the Audio Version

In the pharmaceutical industry, efficiency and cleanliness are paramount, especially when it comes to the preparation of ampoules for the packaging of medicines, vaccines and other liquid-based pharmaceutical products. Automatic ampoule washing machines play a crucial role in ensuring that ampoules are thoroughly cleaned, both internally and externally, before they are filled and sealed. The design and functionality of these machines are continually evolving, with particular emphasis on improving changeover processes - a key factor in reducing downtime and optimizing production efficiency.

One of the major challenges faced by pharmaceutical manufacturers is minimizing downtime during the cleaning process, especially when switching between different production runs. A rotary ampoule washing machine, is engineered to handle these challenges by allowing for quick and efficient changeovers. This capability not only helps in reducing production halts but also enhances maintenance workflows, ensuring that the machines continue to operate smoothly and consistently.

The Importance of Easy Changeovers in Pharmaceutical Manufacturing

In a pharmaceutical manufacturing environment, machine downtime can have significant financial and operational consequences. This downtime is often caused by lengthy changeover processes, where machines need to be reconfigured to handle different sizes, shapes or types of ampoules. Additionally, the cleaning cycles themselves can be time-consuming, especially if the machines are not designed for easy adjustments.

The automatic ampoule washing machine helps overcome these challenges by incorporating features that allow for quick changeovers, even between different production batches. This means that when the type of ampoule or the cleaning specifications change, operators can quickly adjust the machine’s settings and components, minimizing the time spent on reconfiguration. The result is a significant reduction in downtime and, consequently, increased production efficiency.

Design Features That Enable Quick Changeovers

Rotary ampoule washing machines are designed to optimize both the cleaning process and machine flexibility. These machines are typically divided into three basic sections: the mechanical drive, washing section and filtration section. Each section is isolated from the others to prevent cross-contamination and ensure the smooth operation of the washing and cleaning process.

One of the standout features of these machines is their continuous rotary travel system, which allows for uninterrupted operation and easy transitions from one batch to the next. This system ensures that ampoules are held in an inverted position throughout the washing stages, allowing for thorough cleaning of both the inner and outer surfaces.

The automatic rotary ampoule washing machines are built with spray tubes that travel in synchronism with the ampoules, ensuring that the cleaning solution is applied uniformly. The spray tubes, equipped with orifices precisely aligned with the center of each ampoule, provide effective cleaning at each station. As the ampoules pass through the machine, the spray tubes retract once the cleaning stage is complete, ensuring continuous flow.

Another design element that facilitates quick changeovers is the easy-to-remove parts, which are key to ensuring the machine can be quickly reconfigured for different production runs. Whether it is a change in ampoule size or the need for a different cleaning solution, automatic ampoule washer machines are designed to accommodate rapid adjustments. This minimizes the amount of time spent on maintenance and changeovers, enabling a more streamlined production process.

How Easy Changeovers Reduce Downtime

Downtime in manufacturing is not only costly but can also disrupt production schedules, delaying product delivery and affecting overall efficiency. By ensuring that changeovers are completed quickly, automatic rotary ampoule washing machines help manufacturers maintain continuous production. This is particularly important when manufacturers need to switch between different production batches or cleaning protocols.

For example, if a pharmaceutical company is transitioning from one type of ampoule to another, the ampoule washer machine allows operators to easily adjust settings such as spray pressure, nozzle alignment and cleaning cycle duration. In addition, many rotary ampoule washing machines come with features that support the quick replacement of parts, such as spray tubes or filtration units, ensuring that the washing process remains effective even when switching between different product requirements.

The ability to perform quick changeovers also helps minimize the time spent on machine preparation and cleaning, ensuring that the ampoule washing machines are ready for the next production run without prolonged interruptions. This reduces bottlenecks in the overall production process, enhancing the throughput and ensuring that operations remain on schedule.

Improving Maintenance with Easy Changeover Systems

In addition to reducing downtime, easy changeover features in automatic ampoule washing machines also significantly improve the maintenance process. Machines that are easier to adjust and clean are less prone to breakdowns and wear over time, as operators can maintain them more efficiently. Furthermore, these machines are typically designed with high standards of sanitation in mind, meaning that they are easier to disassemble and clean between production runs.

For instance, the filtration section of rotary ampoule washing machines is housed in a separate compartment, which helps isolate contaminants and makes it easier for maintenance teams to access and clean the parts. In addition, the mechanical drive and other components are built to ensure that they can be serviced quickly, without the need for extensive downtime. This minimizes the frequency of complex maintenance tasks, helping manufacturers avoid costly repairs or lengthy service intervals.

The ability to quickly replace parts or switch between cleaning protocols also ensures that the machine remains in optimal working condition. For example, when an ampoule washing machine needs to be serviced due to wear and tear, easy-to-remove components such as the spray tubes or nozzles can be replaced quickly, reducing the time the machine is out of commission and ensuring that maintenance does not disrupt production for long periods.

Increased Flexibility in Production

The ease of changeovers in automatic rotary ampoule washing machines also leads to increased flexibility in the manufacturing process. This is particularly important in the pharmaceutical industry, where products often vary in size, volume and type, requiring machines that can accommodate a variety of specifications. The ability to switch between different ampoule sizes or cleaning standards without significant reconfiguration helps manufacturers maintain operational flexibility, ensuring that they can meet changing production demands without delay.

With rotary ampoule washer machines, manufacturers can adjust the settings to handle different ampoule sizes or shapes, without the need for extensive downtime or specialized tools. This allows them to respond to shifts in demand or make adjustments for special orders quickly and efficiently, without disrupting the overall production schedule.

Conclusion

Parth Engineers & Consultant offers automatic rotary ampoule washing machines with easy changeover features are essential for pharmaceutical industry who need to ensure continuous, efficient and high-quality production. By reducing downtime, improving maintenance and offering flexibility for different production runs, these machines help enhance operational efficiency and ensure compliance with stringent industry standards.

With the pharmaceutical industry’s growing demand for efficiency and speed, ampoule washer machines equipped with easy changeover mechanisms are more valuable than ever. These machines allow manufacturers to quickly adapt to changing production requirements, optimize maintenance schedules and minimize downtime - ultimately contributing to more efficient, cost-effective and reliable production processes.

FAQs About Ampoule Washing Machines

Easy changeover features in ampoule washing machines help reduce downtime, improve maintenance efficiency and enhance production flexibility. This ensures that the machine can quickly adapt to different ampoule sizes or cleaning protocols without lengthy reconfiguration.

Rotary ampoule washing machines are designed with components that can be easily adjusted or replaced, such as spray tubes and nozzles. These machines also feature isolated sections, such as the filtration unit, which makes cleaning and maintenance tasks quicker and easier.

With automatic rotary ampoule washing machines, the ability to quickly replace or clean components minimizes the need for extensive maintenance downtime. This results in fewer breakdowns and a more reliable production process.

By allowing for rapid adjustments and part replacements, automatic ampoule washing machines help manufacturers minimize the time spent transitioning between production runs, keeping the workflow uninterrupted and maximizing production efficiency.

Yes, automatic rotary ampoule washing machines are highly flexible and can be easily adjusted to handle different sizes, shapes and cleaning standards of ampoules, making them suitable for a wide range of pharmaceutical products.

About Author

We provide 24 x 7 Customer

Service & Support

Copyright © 2026, Parth Engineering & Consultant ( India ).

Web Design by Opal Infotech