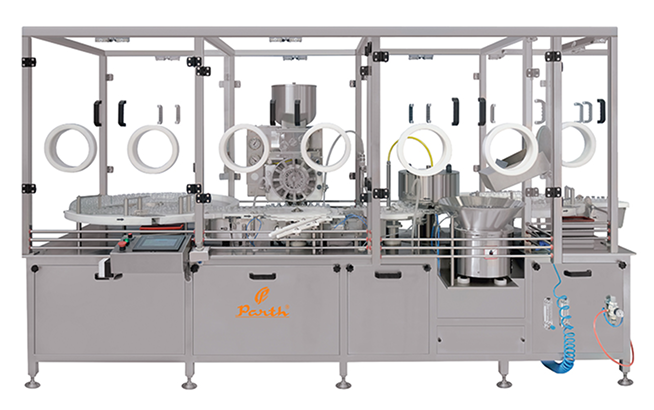

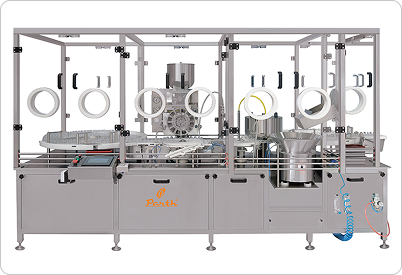

Automated Systems for Vial Filling, Stoppering, Sealing and Dry Syrup Filling Sealing – Designed for the Pharmaceutical Industry

Request a Demo

Ready to optimize your filling and stoppering process? Our expert team is here to assist you

with

tailored solutions that fit your needs.

Reach out for a demo or consultation

today!

Our innovative, high-precision machinery offers reliable solutions for filling and stoppering injectable vials and dry syrups. Engineered for pharmaceutical companies, our systems are designed to ensure maximum efficiency, safety, and quality.

Servo-based PLC control ensures ±0.5% filling accuracy per dose.

Servo-based PLC control ensures ±0.5% filling accuracy per dose.

Integrated pre and post nitrogen purging for aseptic processing.

Integrated pre and post nitrogen purging for aseptic processing.

No Vial–No Filling & No Stopper–Machine Stop safety features included.

No Vial–No Filling & No Stopper–Machine Stop safety features included.

Quick changeover system supports 1 ml to 50 ml vial filling range.

Quick changeover system supports 1 ml to 50 ml vial filling range.

No Bottle–No Fill and No Cap–Machine Stop safety systems ensure zero

wastage.

No Bottle–No Fill and No Cap–Machine Stop safety systems ensure zero

wastage.

Vacuum-based powder filling with ±2% accuracy and adjustable volume

control.

Vacuum-based powder filling with ±2% accuracy and adjustable volume

control.

Pick & Place capping with torque-adjustable screw/ROPP capping heads.

Pick & Place capping with torque-adjustable screw/ROPP capping heads.

cGMP-compliant design with optional PLC control and acrylic dust protection

cabinet.

cGMP-compliant design with optional PLC control and acrylic dust protection

cabinet.

Automatic Servo-based vial filling and stoppering for dry powder.

Automatic Servo-based vial filling and stoppering for dry powder.

High precision and minimal product wastage.

High precision and minimal product wastage.

Optimized for pharmaceutical production lines.

Optimized for pharmaceutical production lines.

User-friendly interface for seamless operation.

User-friendly interface for seamless operation.

Our machines are built with the latest servo-based technology for unparalleled precision and reliability in pharmaceutical manufacturing.

Designed for fast, continuous operation with minimal downtime, maximizing your production output and efficiency.

Our systems easily integrate into your existing production line for smooth transitions and minimal disruption to operations.

Meet the highest industry standards with our GMP-compliant equipment, ensuring regulatory compliance and product quality.

With a strong international presence, Parth Engineers & Consultant exports high-performance pharma machinery across the globe, backed by seamless logistics and support.

Enjoy peace of mind with responsive after-sales service, including remote diagnostics, spare parts supply, and assistance whenever needed.

Join industry leaders who trust Pharmachitectural for their critical manufacturing needs